Home >> Machinery >> Construction Materials & Equipments >> Sandwich Panel >> Details

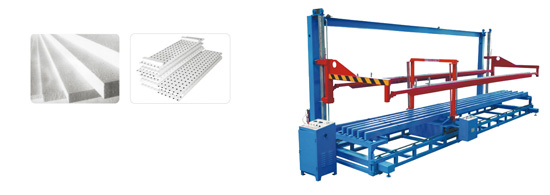

EPS Sandwich Panel Production Line

The product is new generation soap producing machinery based on advanced international technology and many overseas product analysis with optimizing design and high level in domestic market.

CLIMA is a professional EPS machinery manufactory integrating R&D, production, sales and service. Formed in 1988, with the twenty years of development, Now, CLIMA have Five sub-companies, Over ten offices inside and outside of china with over 700 members. Yearly around 2000 sets EPS machines and 1000 EPS moulds outputs, which keep CLIMA as the leading EPS machinery manufacturer in China. Up to now , CLIMA not only have covered all over china, But also are exported to more than 70 countries.

|

|

||

|

|||

|

|

|

MAIN FEATURES |

|

|

|

|

Main Features 1.The main frame of the machine is weld ed from square profile steel, with strong structure, high strength adn no deformation; 2.the machine has horizontal,vertical and cross cutting devices, and can realize 3-direction cutting , i.e. horizontal, vertical and cross cutting; 3.The machine daopts converter speed goveming advantageous in stable moving, large range(0-4m/min)of step-less speed governing, suitable for rwquirements of low-speed cutting and fast cutter-retract; 4.Voltage adjustment: adopts 10KVA multi-tapped special transformer for adjustment with wide adjustable range and multiple voltages; 5.C type cutting machine has multi-wire cross cutting system, use motor and converter to motivate cutting frame upward and downward. Maximum 20wires can be set for cross cutting. |

|

|

|

|

This production line can produce and compound tile panel. The whole line consists of uncoiler, cutting set, - compound system ( ribbon, gelatinizing, heating up, compounding, crimping, notching, edge trimmer, automatic cutting )and is computer operated, which is necessary to manufacture roof and wall panels for industrial workshop and warehouses. It is to produce E.P.S sandwich panel for wall, roof which is used for warehouse, factory, fabricated building. The feature of this panel is able to be easy, fast construction. Because our factory is based in Shanghai China, our price is extremly lower than other countries,however our service and quality are excellent. |

|

All the data are base on our 20 EPS Sandwich Panel Production Line and are only for customers' reference, we can adjust the specification according to your requirements.

Just a few of them have been listed , please contact us if you want any other kinds of machines.

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian