Home >> Machinery >> Steel Products & Steel Processing Machinery >> Welded Pipe Line >> Details

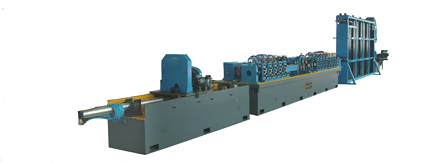

High Frequency Welded Pipe Production Line

The product is new generation high frequency welded pipe productobased on advanced international technology and many overseas product analysis with optimizing design and high level in domestic market. For detailed information,please visit www.welding-pipe.cn

CLIMA can supply different High Frequency Welded Pipe Production Line with different capacity. Please don't hesitate to contact us if you get any question. For more detail information, please visit our webisite about the welding pipe productio line:www.welding-pipe.cn

We are also excel at building a plant for the stainless steel welded pipe and excute turnkey projects.

|

|

|

Our innovative production line and each single unit of the production line are not only economical but also practical. The complete production line adopts ZTF technology when producing round pipe, the customer shall reduce 60% expense on tooling and improve production efficiency and gain maximum economic benefit. |

|

|

|

|

This production line is specially used for producing high-frequency straight seam welded pipe and special-shaped pipe. |

|

|

|

|

High frequency welded pipe mill is the main equipment in the high frequency welded pipe production line. It can be divided into different types according to the diameter and the wall thickness of the pipe. The mill can produce circular pipe, square and rectangular pipe and special pipe with the material of low carbon steel & alloy steel. |

|

|

|

|

High frequency longitudinally welded pipe production line is used to manufacture welded steel pipes of Φ16mm-Φ165mm with 1.5mm-5.0mm of wall thickness, which also can produce profiled pipes within the limit of processing round pipes, such as the square pipes. After absorbing advanced pipe making technology from both abroad and domestic, our innovative designed production line is not only economical but also practical. |

|

All the data are base on our 20 high frequency welded pipe prodction line and are only for customers' reference, we can adjust the specification according to your requirements.

Just a few of them have been listed , please contact us if you want any other kinds of machines.

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian