Home >> Machinery >> Agriculture Equipments >> Chincken Manure Equipment >> Details

Chicken Manure Equipment

Introduction of Chicken Manure Equipment

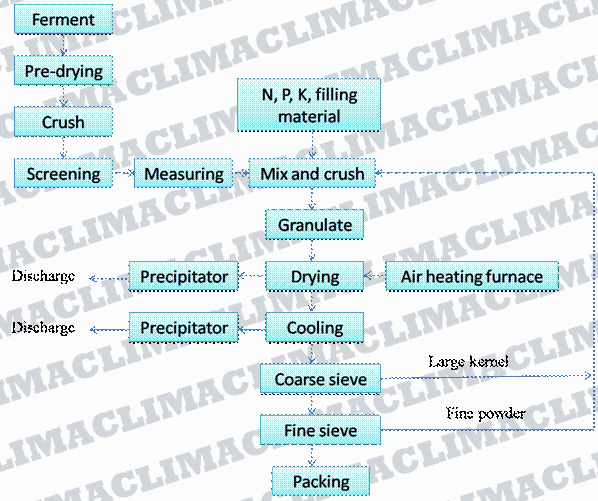

With the development of aquaculture, the pollution of livestock’s dejecta is becoming more serious. The best solution to that problem is to make the waste into useful thing by reclamation treatment. The livestock’s dejecta contains a lot of organic matter that make it a kind of ideal manure. Our project and equipments use organic-inorganic compound fertilizer whose organic matter come from the dejecta of chicken and inorganic raw material come from urea, monoammonium phosphate, muriate of potash, single superphosphate, ammonium bicarbonate, and make pellet manure by a pan granulator with low cost and high efficiency.

Our Chicken Manure Equipment are of high quality .If you are interested in it, please don't hesitate to contact me. We will provide you good quality and low price.

The Production Line of Chicken Manure Equipment

1, Pre drying

Material contains 40-50% of water after ferment and can’t be granulated. Our machine can dry the water content in the material to be about 20%.

2, Crushing

After ferment, animal dejecta should be crushed. Our particular equipment for organic matter can crush the material to be in certain condition.

3, Adding auxiliary materials

Two belt weigh meters control the matching percent. The feed opening is flush with the ground so that reduces work force and as well make the feeding smooth to ensure better granulating effect.

4, Mix and crush

Our horizontal crushing machine crushes the material well and prepare for the next process of granulating. The material contains both raw material and return material.

5, The selection of granulating method

It is important to choose a method of granulating in the production of pellet organic manure. The most popular method in the industry are pan, rotary-drum, extrusion, they have different advantages and disadvantages. Pan granulator is more easy to control, has higher pellet yield and easy to maintain, so our production line adopts pan granulator.

6, Drying process

Ourφ1.8×18m drier is designed especially for organic manure for its low intensity. By our technical revolution, material is raised up by a board hang in the air and heated by hot wind to lose moisture quickly. After that, the material will have less water and higher intensity.

7, Cooling process

Cooling machine is kind of like drying machine, the material is raised up by a board to be in the wind to cool down. Meanwhile, material in this process also loses water.

8, Screening

There is still powder in the cooled material, so we use screen to separate the material, both powder and large pellet are conveyed back to the crusher. And the finished product will be ready for packing.

9, Packing

Both powder and pellet product are automatically filled, weighted, and packed. It is easy to operate and have high efficiency.

Technical Parameter of Chicken Manure Equipment

| Main Raw Material: | Chicken Dejecta, |

| Other Material: | Urea, monoammonium phosphate, muriate of potash, single superphosphate |

| Product: | Organic-inorganic compound manure |

| Power Supply: | 250kw |

| Worker number: | 15 per shift, 45 for 3 shifts |

| Other cost: | USD 18 per ton (Water 70 kg per ton, Electricity 50 kwh per ton, and labor cost) |

| Year output: | 36000-57600 ton |

| Working day per year: | 300 |

| Daily output: | 120-192 ton (depends on the material matching) |

Main Machines Chicken Manure Equipment

1. Chicken Manure Drier

Chicken manure dryer FeaturesChicken manure dryer is a low-fuel-consumption and high efficiency of drying equipment. It can be be used to dry the material with a moisture content below 85% to a final moisture content below 13%,. It is applicble in animal farming, food brewing, sugar and pharmaceutical industries dealing with high humidity waste, as well as a variety of chemical raw materials, such as chicken manure, wine slot, furnace slag, fructose slag, slag vinegar sauce, sugar beet residue, animals slaughtered contents, coal slime, bentonite, etc. It is for resource development and good environmental protection equipment.

The equipment uses downstream drying process, especially suitable for fast drying the humidity materials which need to preserve nutrition, for example, the drying of fresh chicken manure can achieve the purposes of drying, sterilization, deodorant and preservation of nutritional. The dryer is equipped with high-speed rotating drum of crushing devices, which increases the contact area between material and drying medium, the internal unique equipment design, makes materials difficult to adhere to the drum wall panels and parade. The complete machine has the effects of heat preservation, good sealing performance, and the fact that the thermal efficiency considerably higher than the general drum dryer.

The dryer structure is compact, easy to install and debug, and using small floor area. Drum and crushing device use stepless speed regulating devices, which can adapt to the different requirements of the drying materials. The dryer can combine th use of different fuels (such as coal, heavy oil, natural gas, etc.).

Facilities and work principle

The complete sets of equipment mainly is composed of the crushing drum dryer, burning furnace, feed spiral, output spiral, pipeline, dust collector, airlock, air induced fan, electric control cabinet and other components.

Work principle

Humidity materials are conveyed from the feed screw directly into the dryer drum, raised by the drum wall panels repeatedly, and scattered by the crushing blow dispersion devices. Materials and the negative high-temp media are combined sufficiently to complete heat and mass transfer process. As the result of the drum wind angle and the induced air, the feed materials move slowly, and discharged from the spiral after drying, the exhaust gas handled by the dust precipitator, venting to the atmosphere.

2. Pan granulato

After the shipment of Chicken Manure Equipment, we can sent engineers to customers' workshop for installation. Local staffs who will operate Chicken Manure Equipment will also be trained during the assembly.

Just a few of them have been listed , please contact us if you want any other kinds of machines.

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian